Cutting edge logic systems to serve your challenges

CREA® control platforms offer holistic process control solutions, built as a network of modular control blocks including synergies within, providing customized tools to empower you and your equipment to address your challenges across the whole water cycle: reliable and enhanced process performance, reducing operational costs, reducing environmental impact, and/or building resilience against climate change.

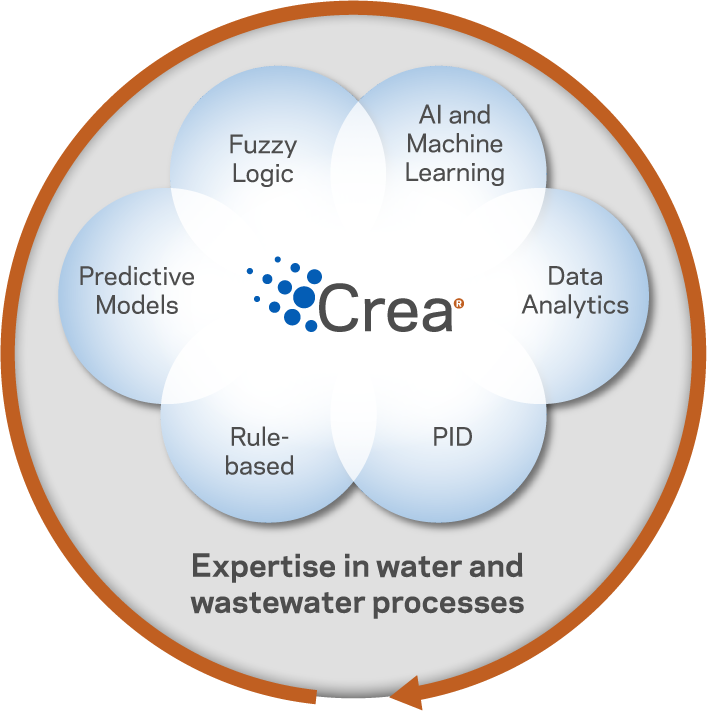

The control modules are the cutting edge engine powering the CREA® platforms: using a combination of advanced logic tools tailored to each application (incl. Artificial Intelligence, Machine Learning, Fuzzy Logic) together with PIDs and modelling where relevant, and rule-based conditions that enables us to include any specific requirement from your site or your equipment. Together with enhanced monitoring and a transparent control tool fitted with editable configuration parameters, our control solutions will empower operations teams to stay in control of their process, control strategies and priorities.

CREA® digital platforms also offer many user experience and process intelligence features, irrespective of the modules it hosts, [Read more]

Modular control solutions for a holistic approach

We design and deliver control process, data management and alert system solutions for the whole water cycle, that can be implemented as single modules, or integrated solutions covering a wider scope.

Our solutions are fit for purpose: selected and adjusted to your site / project, and to enable synergies between control modules where relevant. In short, we have a very wide range of modules installed on our reference sites, and continuously improve and expand depending on projects needs: so our portfolio is not a pick&mix off a catalogue.

See below a list of our most popular module types, which we can customize for your particular application.

DRINKING WATER

Flow and Energy management: adjusts the raw water abstraction from multiple sources to the real-time and forecasted demand. Prevents abrupt changes in water flow and takes into account the quality of each raw water source.

Early Warning system: includes predictive modelling to anticipate climate events and water quality issues, in order to support the best integral management strategy of the water supply system.

Real time management of the processes & predictive features that allow an enhanced performance of treatment units and optimisation of chemical usage.

Provides an effective response to raw water quality variations and takes prescriptive actions to mitigate the formation of THMs/DBPs.

Leak detection and non-revenue water control. Gains insights from the data generated across the catchment and distribution network to increase its hydraulic performance.

Advanced network managment: integral management of the elements of the distribution network to ensure the best water quality and mitigate the formation of THMs/DBPs, while also reducing process-related water losses and taking into account the energy efficiency strategy.

WASTEWATER

Provides and implements the most appropriate DO setpoint In real-time and N/DN process strategy to optimize nitrogen removal performance at minimum energy cost.

Provides and implements the most appropriate DO setpoint in real-time to optimize organic matter removal performance at minimum energy cost.

Based on real-time oxygen demand, it works hand-in-hand with N-control or C-control to achieve the desired DO at all times, by directly and efficiently controlling blowers (or other) and valves (where applicable) through a dynamic pressure control and a Most-Open-Valve strategy.

Direct control of internal (liquor) recirculation pumps, to optimize nutrient removal at minimum energy cost.

Direct control of sludge recirculation pumps, to reach the desired sludge management strategy at minimum energy cost.

Based on N removal performance and temperature, it adjusts WAS level (directly controlling pumps or via DSS), to ensure optimum sludge age.

Based on sewer monitoring in strategic locations, it includes smar tmonitoring, insght and alarms on industrial discharge (general and events). Early warning alerts feed process control modules.

Based on sewer network monitoring and weather forecast, it optimizes the use of retention structures and flow management devices to monitor and minimise CSO.

Direct control of chemical dosing pumps, to reach the desired PO4 level in the effluent with minimum chemical usage.

Direct control of chemical dosing pumps, to reach the desired nutrient removal performance with minimum chemical usage.

Direct control of chemical dosing pumps, to reach the desired treatment removal performance with minimum chemical usage.

Based on time-of-use tariff, it optimizes the use of homogenization tanks to push treatment load towards more cost-effective timeframes and manage treatment load.

SLUDGE

Direct control of dewatering feeding pumps, polymer dosing pumps and (where applicable) decanter machine, to optimizes dewatering performance and polymer usage based on the desired strategy.

Based on biogas production, storage status and kWh cost, it defines the CHP operation strategy in real-time to maximises power production return via sale or on-site consumption based on consumption patterns.

Direct control of dosing pumps (if any) and thickening equipment to increase process performance while minimizing chemicals usage, based on the desired strategy.

Increased AD process robustness and reliability through real-time supervision of key process KPIs, to define real-time strategy to improve organic matter removal and biogas production.

PROCESS INTELLIGENCE AND ANALYTICS

Based on calculations or power consumption records, provide data analytics and management of energy usage and cost.

Advanced data analytics of monitoring equipment to continuously assess signal reliability, corrective actions as well as support instrumentation maintenance planning. Can be enhanced by coupling with CREAlab to include lab data in the assessment.

Tracks and analyses energy consumption data and provides KPIs and warnings to other control modules to improve process control, detect early warning of equipment failure and deviations.

Advanced data analytics including machine learning and soft sensors (instrument digital twins) to further improve monitoring performance and reliability, and in turn process control performance and reliability.

Enables the upload of off-line data (by hand or file upload) to enable data digitalization, comprehensive process overview and deeper process intelligence, by joint data management and analytics of both online and offline data sources.

Solutions customized to suit your needs.

BENEFITS

Models, expert knowledge, PID, artificial intelligence, fuzzy logic, rule-based, pattern recognition and machine learning… as appropriate.

Tailored editable settings, self-customized alarms and reports. No black box: your site, your operation strategy.

Tailored editable settings, self-customized alarms and reports. No black box: your site, your operation.

Dynamic self-adaptive setpoints, signal reliability assessment. Resilient system able to adjust the solution to any future equipment, structural or consent change.